增加油井采油产量的专利产品——市楼星牌ZY型增油短节

目前,全国各油田使用的抽油泵,其柱塞与泵筒之间均采用间隙配合,这样势必存在着漏失问题。漏失导致泵筒内负压减小,影响进油量。漏失量的大小除受泵的精度(即柱塞和泵筒的间隙大小)影响外,还与漏失面上部的油柱压力有关。因此,减小深井内作用在抽油泵柱塞上的油柱压力,以减小漏失量,是提高抽油泵效率的又一新途径。

随着长时间的开采,油井深度的逐渐增加,抽油杆的弹性伸长会越变越大,冲程损失会日趋严重;特别是进入开采的中后期时,长期的地质变化,会致使套管腐蚀变形,造成油管弯曲,从而导致油管连接扣部位产生漏失。总之,种种原因降低了原油产量,给生产带来很大经济损失。

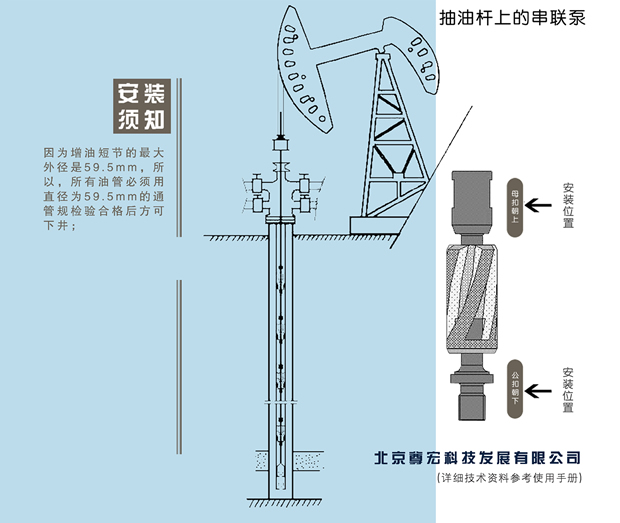

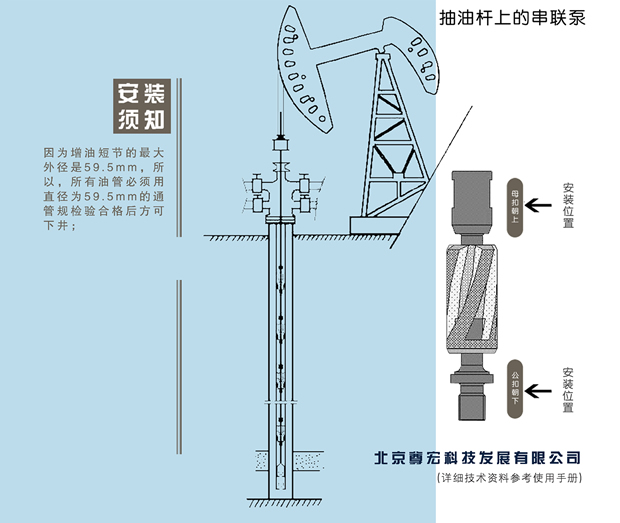

为了解决以上问题,我公司研制、开发了专利产品——市楼星牌ZY型增油短节。它是在不改变抽油泵工作状态的情况下,降低漏失量、减小冲程损失、提高抽油泵效率的新型井下工具。安装了增油短节,相当于在每一根抽油杆上安装了一个提油活塞,使原来油井内的一个抽油泵活塞变成了几十个提油活塞,也可以说相当于在抽油杆上安装了几十个串联泵。这种分段提油的方法大幅度减小了抽油泵柱塞上的油柱压力,不仅减小了抽油泵的漏失,使泵筒内形成较高负压,增大进油量,提高了抽油泵充满系数;而且在分段提油作用下,减小了油管扣漏失,减少了抽油杆在上行程时的弹性伸长,即:减少了冲程损失,从而达到了增加原油产量的目的。

工作原理:

市楼星牌ZY型增油短节安装在两根抽油杆的连接处。当抽油杆下行时,游动凡尔打开,使原油经四孔流道顺利通过;当抽油杆上行时,游动凡尔关闭,密封油道。此时,油管内的原油随抽油杆的上行运动一起被上提,完成一个抽油过程。在油井中安装增油短节,除有增油作用外,它还可替代扶正器、刮蜡器和变扣接头的工作。所以,任何一口油井,如果安装了“市楼星牌增油短节”,便不必再装扶正器、刮蜡器和变扣接头(结蜡的井段和斜井拐角井段除外),由此可节约部分成本。

between oil pipes.

Contra-posing the above problem, our company has developed a new tool, which is able to lower the dropping miss, reduce the stroke loss and increase oil output– Oil Increase Nipple.

The effect created by connecting a number of nipples in tandem to the pumping rod string amounts to that the weight of the liquid column exerted on the plunger is dispersed onto each pumping rod. Lifting the oil in steps lessens the pressure of the liquid column exerted on the plunger, thus reducing the loss of the pump; in the meantime, the same action shortens the elastic elongation when the pumping rod travels up, i.e. decreasing the stroke loss.

OPERATING PRINCIPLES:

Oil increase nipple is fixed in connection of two oil pumping rods. When oil pumping rod travels downwards, the traveling pump valve opens, making crude oil pass the 4 - pore interval channel without obstacles; when the oil pumping rod travels upward, the traveling pump valve closes, sealing the oil channel. At this time, crude oil in oil pipeline is lifted as the oil pumping rod moves upward. Up to now, an integrated oil pumping process is over. Oil-increase nipple fixed in the oil well acts not only to increase crude oil yield but also instead of centralizer, paraffin scraper and adjustable joint. Accordingly, an oil well (except for paraffin deposited well section and inclined well turning well section) equipped with an oil-increase nipple needs not to be equipped with centralizer, paraffin scraper or adjustable joint any longer, thus saving a great part of the cost.

|